Mechanical services for all industries in Windsor-Essex.

Mechanical services for all industries in Windsor-Essex.

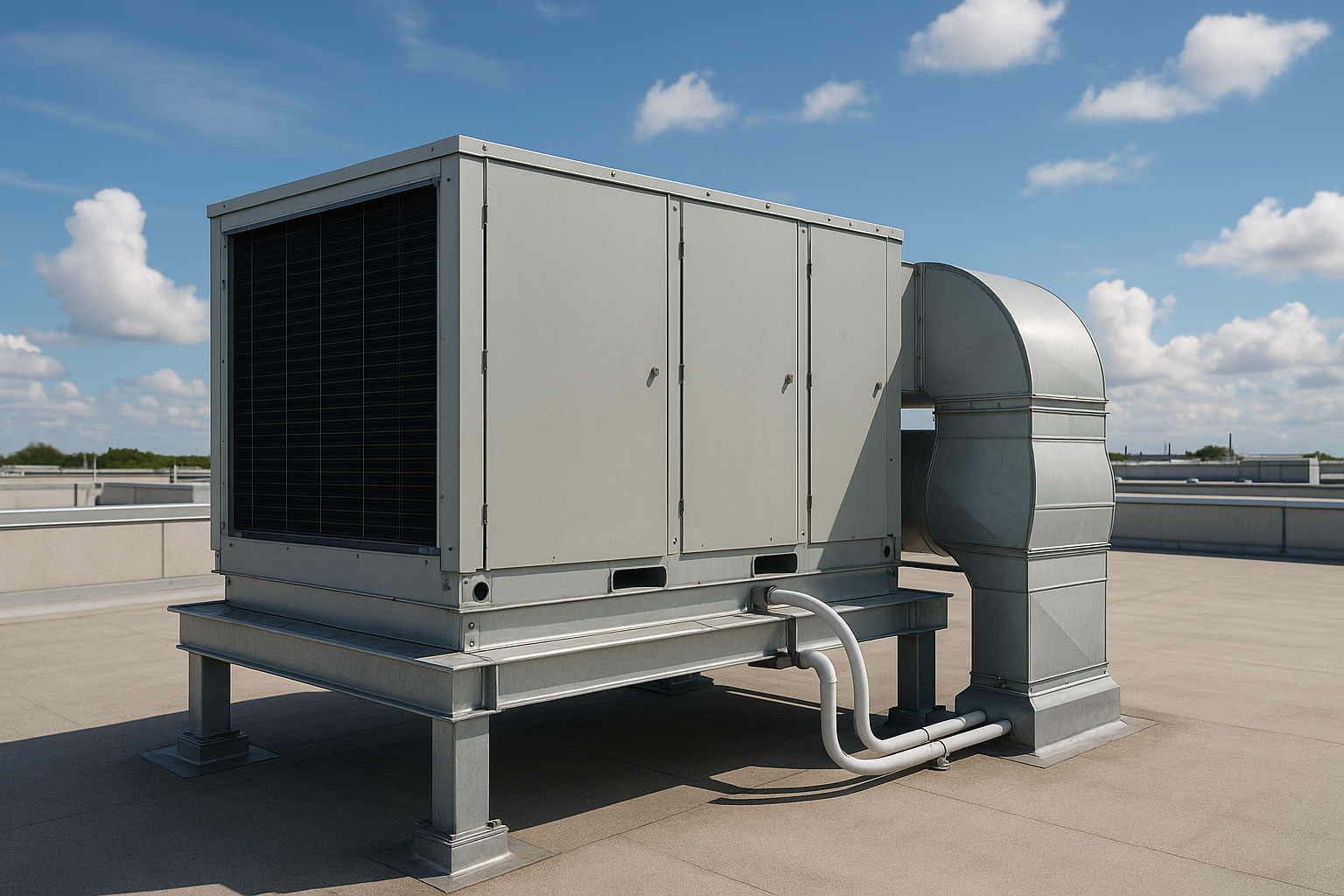

Industrial facilities operate under pressure. High loads, strict safety requirements, and non-stop workflows. Your HVAC system needs to support that without fail.

At Mailloux Mechanical, we deliver certified industrial HVAC services in Windsor as part of a full-service mechanical approach built for scale, efficiency, and long-term reliability. From custom system design to full mechanical installations, we’re equipped for high-performance environments.

With over 50 years of combined experience, we know how to handle the unique challenges of industrial facilities—and we bring that expertise to every project.

Reliable mechanical services go beyond comfort. It’s about energy efficiency, peak performance, system longevity, and protecting your bottom line day in and day out.

Save energy and reduce operating costs with modern equipment designed to handle high-demand environments efficiently.

Engineered layouts tailored to industrial workflows, safety zones, and facility performance needs.

Centralized system control for temperature, ventilation, and runtime tracking with smart energy management built in.

Ensure safe, code-compliant infrastructure with professional plumbing evaluations and industrial-grade correction services.

We start with a conversation to understand your goals and challenges.

A detailed walkthrough to evaluate your current setup and work scope.

Tailored solutions based on your budget, performance, and facility.

Clean installs, clear updates, and follow-through for performance.

Our team provides complete industrial mechanical and HVAC solutions to support safety, workflow, and compliance in your facility.

Airflow and exhaust control

High-capacity HVAC units

Efficient temperature control

Pressure & air balance

Custom duct solutions

Cleaner work environments

Safe fuel distribution

Unexpected shutdowns cost time and money. Our proactive approach to HVAC maintenance and upgrades ensures your system stays efficient, compliant, and ready for anything.

Regular maintenance is the key to long-term system reliability. Our preventive programs include scheduled inspections, cleaning, diagnostics, and performance checks that help avoid costly breakdowns and minimize unplanned downtime.

For higher-demand operations, we also offer predictive maintenance that monitors real-time system data to identify wear, inefficiencies, and failure risks before they happen. It’s a smarter way to maintain uptime, reduce costly repairs, improve energy efficiency, and protect your equipment investment over the long term.

If your current HVAC system is underperforming, we can upgrade or retrofit it with modern components that improve airflow, energy efficiency, and control. These updates help extend the life of your equipment without the cost of full system replacement.

Each upgrade is tailored to your facility’s existing infrastructure, reducing downtime and avoiding major disruption. We’ll recommend solutions that meet your goals for comfort, compliance, and long-term operational savings, while improving safety and performance throughout your building.

When your system fails, you can’t afford to wait. That’s why our licensed technicians are available 24/7 to respond quickly to HVAC and mechanical emergencies in industrial environments of all sizes and layouts.

We arrive ready to troubleshoot and resolve the issue fast, with safety, communication, and performance top of mind. Our goal is to protect your operation, your staff, and your productivity when every minute counts. We’ll get your systems back online quickly, reliably, and with full transparency throughout the process.

Every facility is different. That’s why we offer customized mechanical solutions that include HVAC, designed to meet your goals, budget, and compliance requirements. Let’s start with a conversation and design an HVAC strategy built for your facility.

Industrial HVAC systems are built for larger spaces, higher loads, and complex demands. They must meet strict safety regulations, handle hazardous conditions, and often require custom engineering and high-capacity components to perform reliably.

Most systems need service every 3 to 6 months, depending on usage and industry standards. High-demand environments may require more frequent checks to maintain performance, ensure safety, and stay compliant with regulatory and operational requirements.

Yes! We handle full mechanical design-builds for industrial construction projects. That includes system planning, ductwork, installation, automation integration, and commissioning to meet your facility’s unique performance and code requirements.

We do. Predictive maintenance uses system data and diagnostics to detect wear, inefficiencies, or early signs of failure. This helps reduce downtime, extend equipment lifespan, and optimize energy use before issues escalate.

Absolutely. We upgrade legacy HVAC systems with newer, more efficient components, improved controls, and better airflow. Retrofits improve comfort, energy use, and automation compatibility, and reduce the need for full system replacement.

We serve a range of industrial environments, including manufacturing, logistics, food processing, warehousing, fabrication, and production facilities—any site that requires high-performance, compliance-ready HVAC and mechanical ventilation systems.

Yes! We install ventilation, dust collection, and fume extraction systems to protect air quality, remove contaminants, and meet industry safety codes for worker health and environmental compliance in industrial settings.

Yes. Our technicians are fully licensed, insured, and trained for industrial sites. They follow safety protocols and deliver expert installs, service, and repairs across high-capacity systems and demanding environments.

Mailloux Mechanical was founded by a father and son with over 50 years of combined experience; we set out to build something different: a mechanical company rooted in trust, transparency, and high standards.

Developing Windsor-Essex’s Digital Real Estate | YQG Digital Inc.